- Product Categories

- Technology

- Afterpress

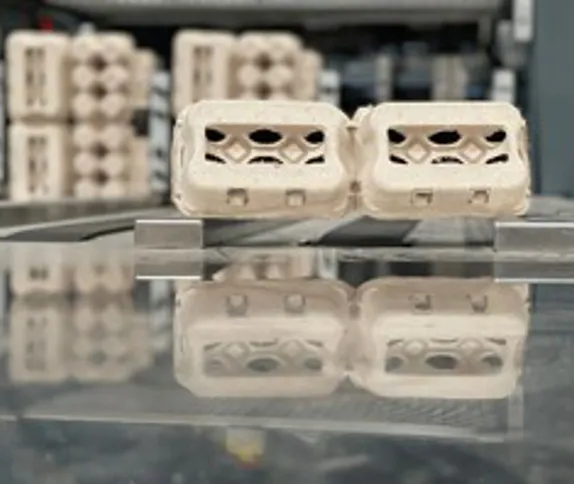

Afterpress for Retail Cartons

Transform your egg carton production with Hartmann Afterpress systems — engineered to deliver a flawless print‑ready surface and consistent carton integrity, whether in-line or off-line.

Designed for two, three, or four carton rows, these systems elevate productivity and operational flexibility.

Seamless Finish - Maximum Output

Hartmann offers two Afterpress models to match your output needs. Choose from 2-4 rows based on carton type, capacity and footprint.

All models feature heated upper and lower tools, automatic thermo‑sensor control, and heavy-duty mechanical components for robust, high‑precision pressing.

The system employs dedicated drive terminals to manage conveyor belts and humidifiers, thus offering full speed control.

Running automatically and synchronized with your moulding machine, the line delivers cartons straight to dry-end handling — ready for printing or labelling.

Key Benefits

Peak efficiency in printing and labelling with flawless surface finishing

Improved denesting and packing due to dense and uniform carton surface

Tailored Afterpress setup to match carton types and capacity

Fewer rejects - Less rework - Maximum cost efficiency

Reduced manpower and downtime through precise product placement.

Accurate synchronization with the moulding machine

Contact Us

Contact us today and explore how our innovative solutions can transform your ideas into measurable growth in moulded fibre packaging production.